It is very important to take care of our teeth as we get older. Brush and floss daily, go to the dentist for checkups as routine suggestions; these are things we all know. But sometimes we need more than typical dental care. This is exactly why dental zirconia milling machines are here to help, and play a crucial role in making sure our oral health stays intact.

Advantages of Dental Zirconia Milling Machine

As an incredibly strong and biocompatible material, zirconia has revolutionized the dental industry. Zirconia is milled using particular apparatus which in turn, increases the physical and mechanical qualities that make for indestructible tooth replacements. Zirconia, does not have that problem as it is a nonmetallic and age-resistant material which cannot corrode unlike metals. In addition to this, zirconia can be bonded with your jawbone while not only improving the bone growth but looks just like real teeth.

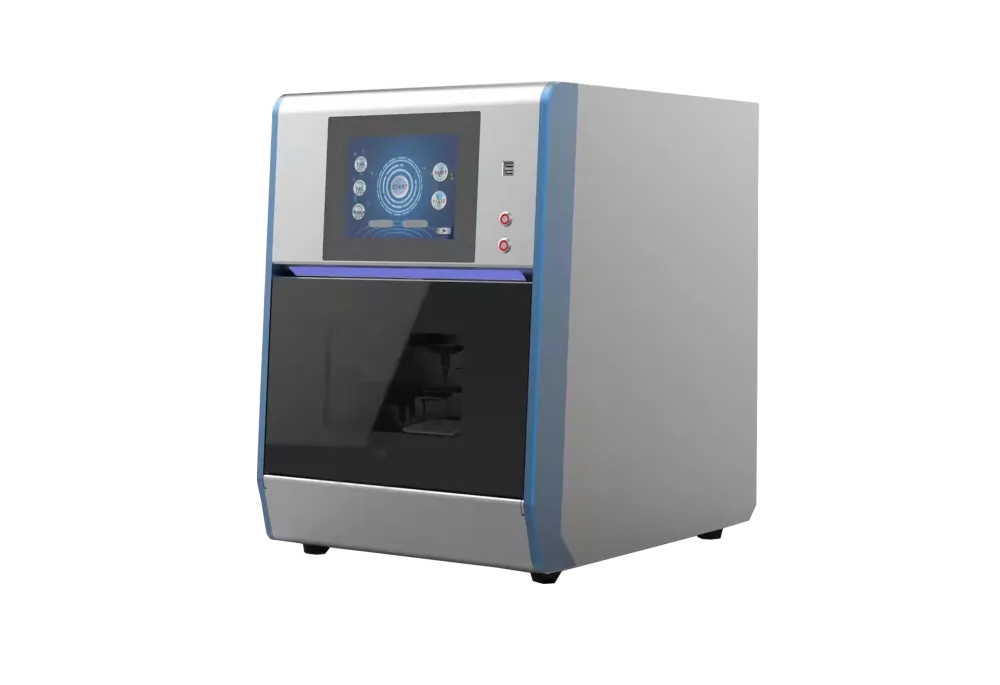

Modern dental zirconia milling machines, such as Roland DG's innovative DWX-52DCi, were developed to make it easier and more efficient for users to produce individualised restorations. The most advanced technology making milling of dental restorations an incredibly accurate and smooth process. Machines like these are able to mill with very high precision because of their use of ultra-precise sensors. On top of that, the incorporation of Artificial Intelligence (AI) technology automates milling processes.

For Example in the past, metals and ceramics were used for dental restorations but metal was subjected to rusting as well as overall fragility. Due to this new adverse effect on the human body, zirconium dioxide has been implemented as a safer option throughout dental restorations. The dental zirconia milling machines include warning sensors such overheat protection that halts the machine automatically in case of malfunction, thereby alerting user. These precautions would assure that it will not cause any harm to the patients as well as their respective operators and protect them from potential dangers suchs heat-induced combustion inside of the milling machine.

Depending on Your Needs: How to Use Dental Zirconia Milling Machines

The Dental zirconia milling machine is simple to unpack. First, users need to create Computer-Aided Design (CAD) files of the desired dental restoration - a step that can also be performed with the scanner equipped on DWX-52DCi. Then the files are sent to milling machine which is used for cutting operations. With the system operating automatically, users can trust that this machine will deliver non-stop accurate restorations.

Zirconia milling machines are durable, versatile devices made from premium-quality materials. Milling Machines to mill all type of dental restorations from crowns, bridges and implants. The zirconia blocks accommodate to different sizes, although the finishing is very precise and this helps a lot in carrying out jobs that fit perfectly for teeth.

Regular maintenance of the milling machines is necessarily done to maintain consistent processing and effectiveness In the digital era, monitoring services are used to notify when maintenance is needed and that everything is working perfectly. Because manufacturer warranties and customer service are included in the price for these machines, you also get added peace of mind knowing that repairs or replacements can be made quickly if necessary.

The advent of zirconia has redefined periodontology into the modern era for its impressive strength and biocompatibility. Proper machines can also mill it which makes materials stronger and the teeth are durable for long time. Zirconia is also hypoallergenic and resistant to corrosion, this makes it a better option for dental use over metals or ceramics. It fuses well with the jawbone and encourages growing new bone, which makes this very beneficial alongside its ability to mimic real teeth.

New Innovations In Dental Zirconia Milling machines

With the ability to greatly simplify manufacturing custom-made tooth replacements, these devices include dental zirconia milling machines like Roland DG's DWX-52DCi which provide high-speed and precision in producing accurate results on dentures. These machines are state-of-the-art in that they provide high-precision sensors for accurate milling and also contain Artificial Intelligence (AI) inside to automate such tasks.

Safety First Feature for Dental Zirconia Milling Machines

In the past, metal was predominantly used to restore teeth as well ceramic crowns that were susceptible to rust and can be extremely easy broken by stress. Zirconia, on the other hand, is highly non-reactive and avoids these drawbacks for dental restorations. In addition, the milling machines of today have built-in preventive systems such as overheating which prevents any operational malfunction and also keeps the parameter in check (safety).

Streamlining Services with Dental Zirconia Mill Machine

It is simple to use, and the setup of dental zirconia milling machines. Initiating the milling process is straightforward for users, as they just prepare CAD files and load them onto the machine. An automated a system to ensure precision milling that results in perfectly finished dental restorations, which will match patients' natural teeth[axis])

How to Make Sure Dental Zirconia Milling Machines are Used Properly - The dos and don'ts

Dental zirconia milling machines are made up of high-quality material so these will work for an extended period. These machines can mill a variety of different types and brand blocks that maintaining accuracy from start to finish ultimately resulting in an improved patients smile through perfect fit restorations.

RD team, sales staff as well experienced after-sales teams highly qualified provide dental zirconia milling machine customizations comprehensive support.

Every product is backed by CE as well as an ISO certification. More than 50 dental zirconia milling machine, and the nation's largest high tech company.

Dynamic, after years development product line covers entire solution dental zirconia milling machine solutions, image dental CAD/CAM includes air compressors suction devices, intraoral scanners, dental milling devices, Phosphor Plate Scanning, dental x-ray sensors, more.

Since the time it was founded in 2004, dental zirconia milling machine., has been committed to RD manufacturing, as well as selling dental equipment. We are home to over 30,000 square meters of industrial space. We also have our own warehouse and factory. Therefore, we are sure to meet the customers' demand, and our products have been sold to over 100 countries and regions around the globe, and have been sold in thousands and gained an excellent reputation thanks to reliable quality, affordable price and quality service.

This is why you need to have a regular maintenance routine for your dental zirconia milling machine, so that it goes on working perfectly well as long as possible. In addition, to guarantee continuous operation even modern models have monitoring structures that warn the user when support work is needed. Again, with extensive warranties and backed by manufacturer customer service you get that piece of assurance knowing help is just a phone call away.