For many years X-ray sensors have been crucial in areas such as medicine and industry. These are the tools that Grace refers to as 'powerful eyes' -they will reveal things of depth, beyond the surface. These improved versions of advanced technologies now benefit everyone today an equipped with gadgets that use the best technology to take photos more safely and accurately. In this article, we will get a bit more into the fascinating x-ray sensing world with some cases in case it lands on your to save lives during scans or cobots at industrial processes and even adds smart sensors for quality control and efficiency.

The Morning After: The future of medical diagnostics helps us see further, clearer and with more detail -- next-gen x-ray sensors In between Those milestone technology advancents will enhance patient care in the form of new images that are not only higher resolution but also require less dose. Now X-ray sensors embedded with artificial intelligence (AI) and machine learning algorithms have become beneficial in detecting diseases earlier, aiding more accurate diagnosis. The have x-ray sensors can be worn and fill the gap between lower-quality scans available every now and at radiological study schedule scannings or none due to ensuing restrictions. Scheduled continuous 24/7 tracking is expected to provide earlier triggers for intervention and personalized treatment plans. Moreover, they provide for "point-of-care" health care delivery and can be taken to the remotest parts of not only underdeveloped countries but also economically developed nations.

X-ray imaging has always had radiation safety as a top priority. Thankfully, state of the art sensor technologies are solving this issue by reducing many orders in magnitude radiation proposition while maintaining if not improving image quality. For instance, direct conversion detectors convert x-rays directly into electricity and thus provide more efficient methods than the traditional ones. More than safe free may scans which still give a comprehensive clinical image serve the interest of long term follow-up to monitor chronic diseases. The x-ray sensors have real-time dose monitoring systems integrated with them, which adjusts radiationsource to individual size and examination criteria - minimizing the radiation exposureon patients.

Sensors are well-received in the industrial sector, with x ray sensors helping them to be more capable of quality control and streamline inspection processes. X-ray sensors find defects, cracks and foreign bodies in materials or products without destroying them. Non-destructive testing (NDT) prevents components from being installed safely Therefore, these sensors are very versatile in the aerospace industry, as well as automotive and electronics manufacturing. They achieve this by giving you high-resolution 3D vision, which can pick up on small surface defects that are invisible to the naked eye but could ruin product integrity and cost recalls. Automation and robotics are used in x-ray sensors making the inspection at a faster rate.

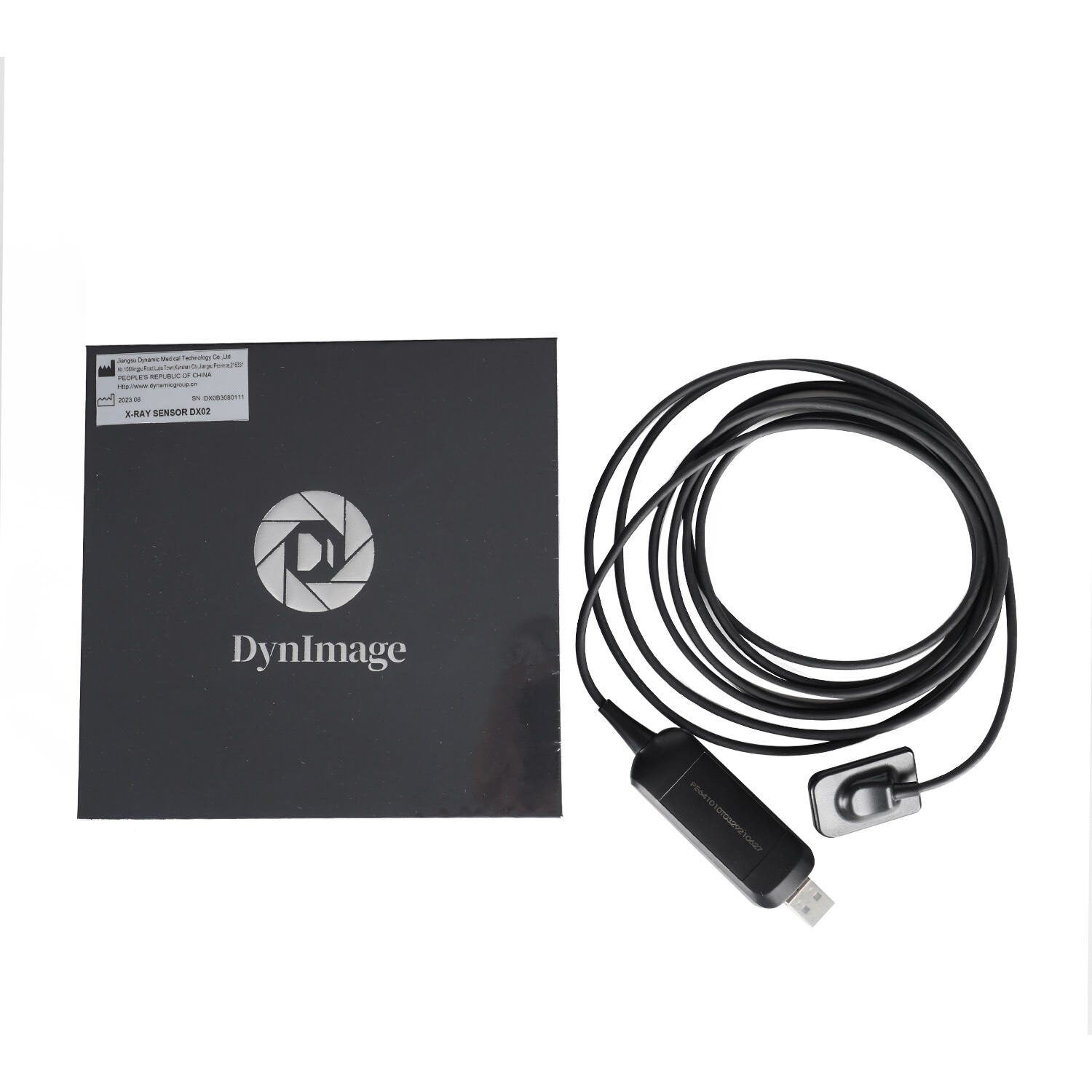

Another revolutionary advancement in the field of dentistry are x-ray sensors, which have transformed routine dental check-ups and advanced procedures. Their modern counterparts are digital intraoral sensors which capture image instantly, with lower radiation exposure and improved diagnostic abilities than traditional film. Are It takes high resolution pictures of your teeth and gums to show cavities (again very clearly), bone loss, or impacted teeth. They are also designed to ensure that they do not take much space and can be easily used without causing any inconvenience to the patient during operation. This workflow facilitates dentists working together locally or from different parts of the country to share patient information and hence allow for a good deal of collaboration in excellent treatment planning.

x-ray sensor, after years development has product line covers entire solution air-supply solutions, imaging, dental CAD/CAM system comprising air compressors, suction devices, intraoral scanners, dental milling machines, dental Phosphor Plate Scanning dental x ray sensors, etc.

products x-ray sensor CE as well an ISO certification. 50 patents registered enterprise that national leader high-tech.

2004, company founded. Jiangsu x-ray sensor Medical Technology Co., Ltd. always devoted RD production, as well sales dental products. We over 30,000 square meters industrial space, own factory warehouse. We're sure please customers, as have sold lot sets, exported over 100 countries earned ourselves great reputation reliable quality, fair prices, good service.

RD team, sales staff professional x-ray sensor team highly trained provide custom-designed customizations comprehensive support.

Intelligent x-ray sensors - and a new era of process control and manufacturing efficiency. These sensors among other equipment - all have a bunch of moisture control is integrated within the IoT enabled devices, allowing them to transmit data back wirelessly, in real-time so that they can be analysed and necessitated actions could be taken. Namely in manufacturing lines - to discover problems in real-time, this could save an immediate corrective action and help reduce waste. Now further enriched into AI-drive analytics, they go a step higher from predicting maintenance schedules to production settings and helps you refine at the improvement spectrum of processes. This automation and intelligence to help maintain the quality of their products, while also improving operational efficiency and profitability.

In summary, x-ray sensors are yet another example of the endless possibilities inhumanely created technology within medicine & industry. As technology progresses and advances, so do the safer, more accurate and efficient offers. Their contributions include revolutionizing medical diagnostics, transforming industrial inspections, improving dental care and making the world healthier; safer & more productive. Each step forward brings us nearer to the promise of these next generation diagnostics and new ways of bringing precision with safety into alignment.